In the bustling world of culinary arts, even the seemingly simplest tasks can hold significance. Take, for example, the act of cracking an egg—a fundamental skill in countless recipes, yet one that requires finesse to execute perfectly. As technology advances, even this age-old practice is undergoing a revolution, with high-tech egg cracking machinery poised to transform kitchens around the globe.

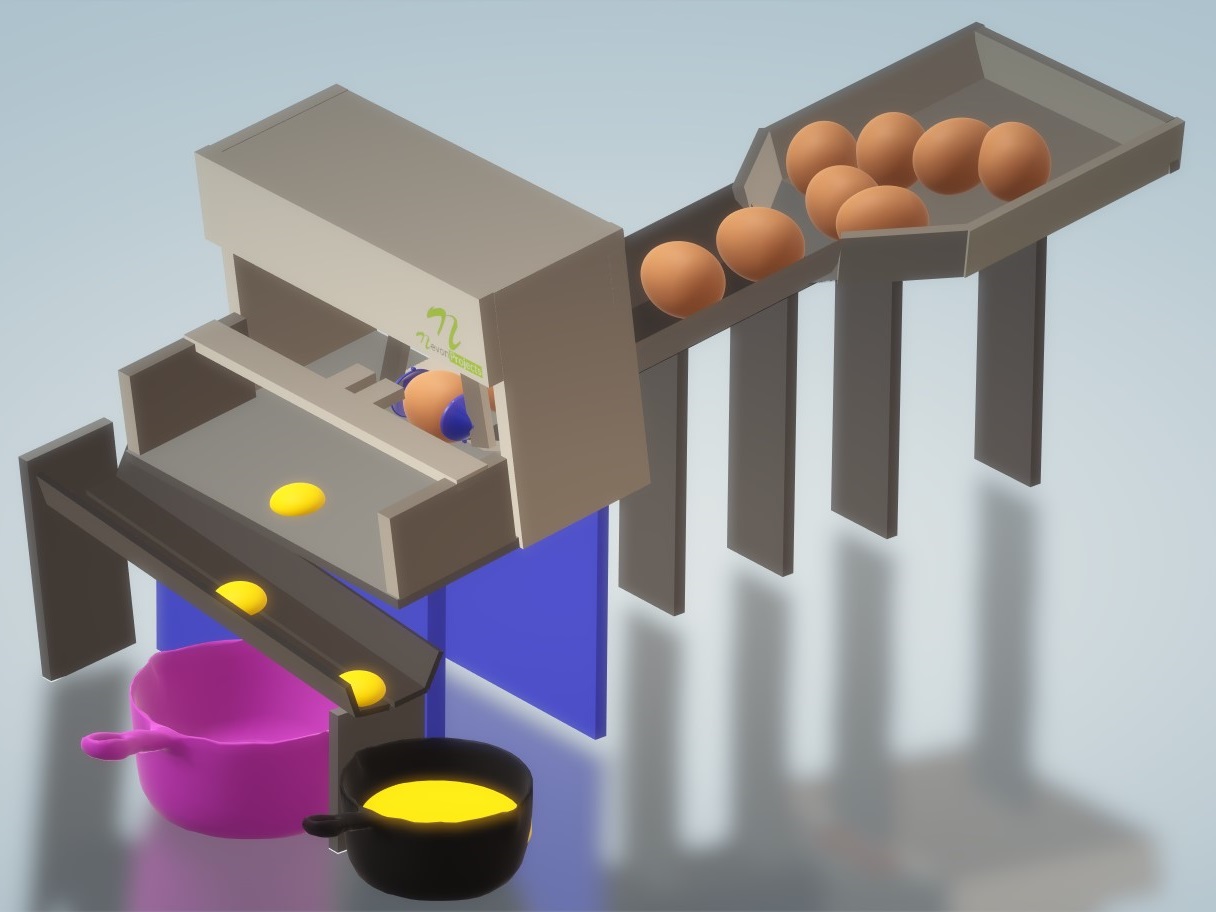

At the heart of this innovation are precision-engineered egg cracking machines equipped with state-of-the-art sensors and robotics. These marvels of engineering are designed to crack eggs swiftly and flawlessly, with a level of precision that rivals the most skilled human hands. Gone are the days of shell fragments littering the batter or broken yolks marring the presentation—these machines ensure consistently perfect cracks, every time.

One of the key features of high-tech cracking eggs machinery is its adaptability. These machines can accommodate eggs of various sizes and types, from small quail eggs to extra-large duck eggs, with ease. Advanced sensors analyze each egg’s dimensions and adjust the cracking force accordingly, ensuring a clean break without damaging the delicate interior. This versatility makes them indispensable tools in kitchens ranging from bustling restaurants to industrial-scale food production facilities.

But the benefits of high-tech egg cracking machinery extend beyond mere efficiency. By automating the cracking process, these machines significantly reduce labor costs and eliminate the risk of human error. In high-volume settings, where thousands of eggs are cracked daily, this can translate into substantial time and cost savings. Moreover, the consistent quality achieved through automation ensures uniformity in recipes, guaranteeing a flawless culinary experience for patrons.

In addition to efficiency and consistency, high-tech egg cracking machinery offers a level of hygiene and food safety that is unparalleled. By minimizing human contact with raw eggs, these machines reduce the risk of contamination and ensure compliance with stringent health regulations. This is particularly crucial in environments where food safety is paramount, such as hospitals, schools, and catering facilities.

Furthermore, the integration of cutting-edge technology, such as artificial intelligence and machine learning, opens up new possibilities for optimization and innovation. These intelligent systems can analyze data in real-time, fine-tuning cracking techniques based on factors like egg size, shell thickness, and ambient conditions. The result is an adaptive and responsive technology that continually evolves to meet the demands of modern kitchens.

As the culinary landscape continues to evolve, high-tech egg cracking machinery stands at the forefront of innovation, redefining the art of perfect cracks. With their unparalleled precision, efficiency, and hygiene, these machines are revolutionizing kitchens around the world, empowering chefs to unleash their creativity and elevate the dining experience for patrons everywhere. Truly, the future of egg cracking has never looked brighter.